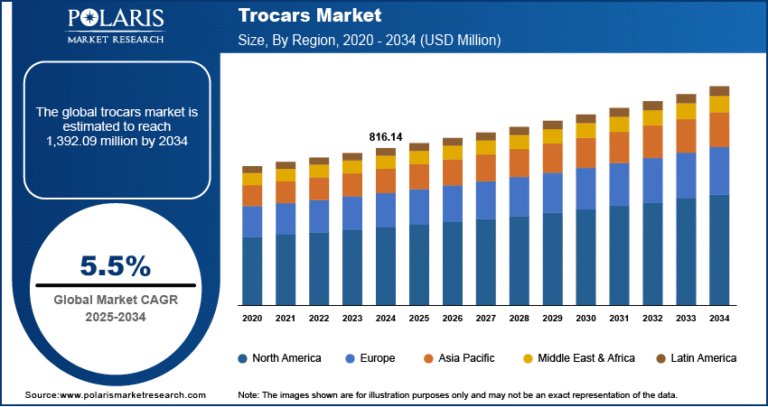

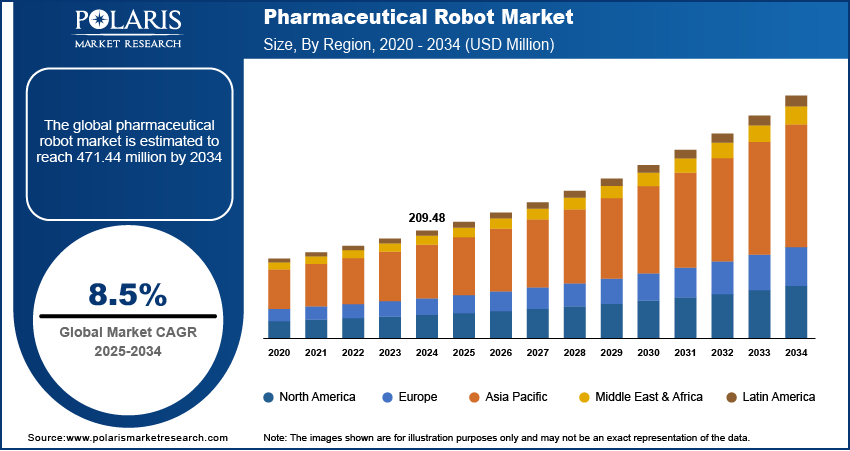

Pharmaceutical Robot Market projected to reach USD 471.44 Million by 2034, expanding at a CAGR of 8.5%

The global pharmaceutical robot market was valued at USD 209.48 million in 2024. It is expected to grow to USD 226.24 million in 2025 and reach USD 471.44 million by 2034, registering a compound annual growth rate (CAGR) of 8.5% over the forecast period. The pharmaceutical robot market is growing rapidly due to rising demand for quality products, cost-efficient production, and increased automation to minimize human error.

Trends & Insights

- Rising Demand for Precision and Safety:

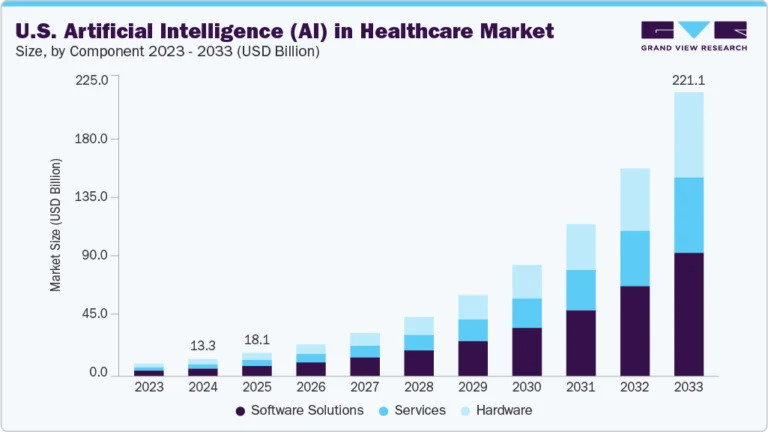

Pharmaceutical robots are increasingly adopted to reduce human error and contamination in sterile drug production and packaging processes, especially in high-precision applications such as drug formulation and micro-dosing. - Adoption of AI-Integrated Robotics:

Integration of artificial intelligence (AI) and machine learning into pharmaceutical robots enables enhanced diagnostics, autonomous task execution, and predictive maintenance—boosting overall operational efficiency. - Shift Toward Automation in Drug Manufacturing:

With rising pressure to reduce time-to-market and improve quality assurance, pharmaceutical companies are automating their processes using robots for tasks such as compounding, filling, inspection, and palletizing. - Shortage of Skilled Workforce:

The global shortage of trained pharmaceutical manufacturing professionals is accelerating the demand for robotic systems to fill critical gaps in production lines and ensure consistent throughput.

Market Size & Forecast (2025–2034):

- Market Size Value in 2025: USD 226.24 million

- Revenue Forecast by 2034: USD 471.44 million

- CAGR (2025–2034): 8.5%

𝐆𝐞𝐭 𝐄𝐱𝐜𝐥𝐮𝐬𝐢𝐯𝐞 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐚𝐠𝐞𝐬 𝐨𝐟 𝐓𝐡𝐢𝐬 𝐑𝐞𝐩𝐨𝐫𝐭:

Market Overview (Generic – 2 Paragraphs):

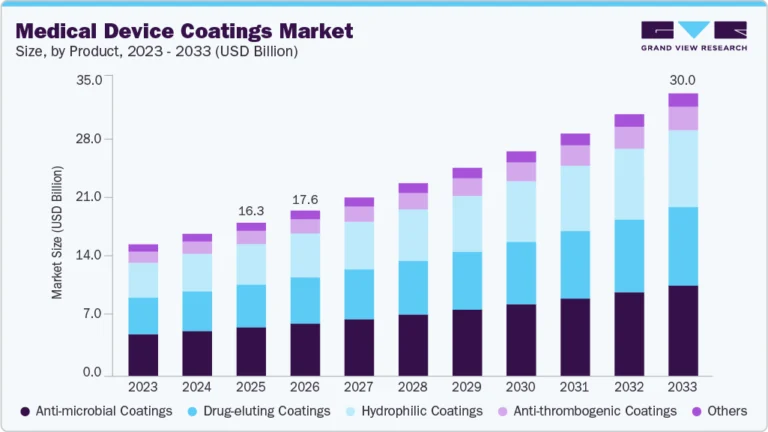

The pharmaceutical robot market is evolving rapidly, driven by increasing automation across pharmaceutical manufacturing and research sectors. These robots are designed to perform repetitive, high-precision tasks in sterile environments, significantly reducing the risk of contamination and human error. Pharmaceutical firms are deploying robots to automate critical stages in the drug development life cycle, from research and laboratory testing to production and packaging. The need to meet stringent regulatory standards and improve the quality of pharmaceutical outputs is further boosting the adoption of robotic solutions.

In addition to manufacturing applications, pharmaceutical robots are being used for material handling, quality control, and even clinical diagnostics. Their ability to operate 24/7 with minimal supervision supports uninterrupted production cycles, ultimately increasing plant productivity and cost-efficiency. As technological advancements in robotics continue—such as vision systems, AI integration, and cloud-based analytics—their capabilities are expanding, paving the way for broader use in advanced pharmaceutical settings.