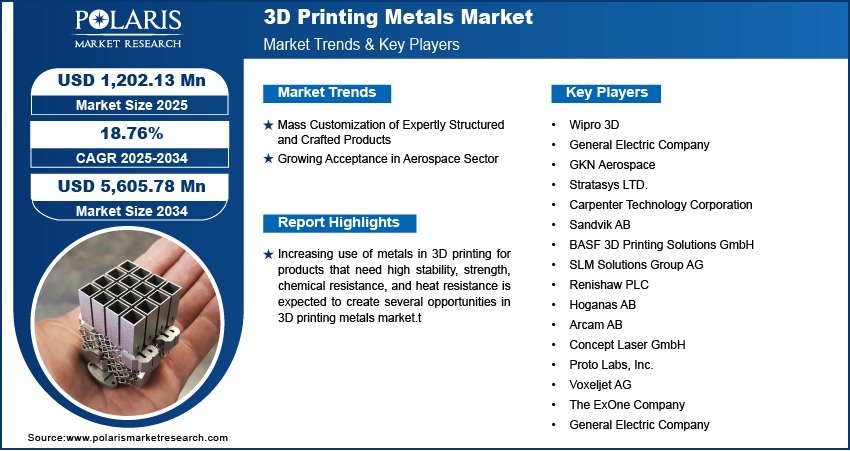

3D Printing Metals Market Projected to Reach USD 5,605.78 Million By 2034, Growing at a CAGR of 18.7%

The global 3D Printing Metals market size was valued at USD 1,014.17 million in 2024 and is projected to grow from USD 1,202.13 million in 2025 to USD 5,605.78 million by 2034 , exhibiting a robust Compound Annual Growth Rate (CAGR) of 18.7% during the forecast period from 2025 to 2034 .

- Rising Demand from Aerospace and Defense: The aerospace and defense sectors are increasingly adopting metal 3D printing for lightweight, complex components that offer high strength-to-weight ratios and improved performance.

- Growth in Medical and Healthcare Applications: Customized implants, prosthetics, and surgical tools fabricated using 3D printed metals are gaining traction due to their superior biocompatibility and patient-specific design capabilities.

- Technological Advancements in Additive Manufacturing: Innovations such as multi-laser systems, hybrid manufacturing, and improved powder metallurgy techniques are enhancing production efficiency and part quality.

- Expansion of Industrial and Automotive Applications: Automakers and industrial manufacturers are leveraging metal 3D printing for rapid prototyping, tooling, and end-use parts with reduced lead times and material waste.

- Increasing Investments in R&D and Startups: Governments and private investors are funding additive manufacturing initiatives, fostering innovation and accelerating commercialization across industries.

Market Size & Forecast

- Market Size in 2024 – USD 1,014.17 million

- Market Size in 2025 – USD 1,202.13 million

- Projected Market Size by 2034 – USD 5,605.78 million

- CAGR (2025–2034) – 18.7%

Metal 3D printing, also known as additive manufacturing, involves the layer-by-layer fabrication of complex metallic components using powdered metals and high-energy sources such as lasers or electron beams. This technology enables the production of highly customized, intricate, and functional parts that are difficult or costly to manufacture using traditional methods.