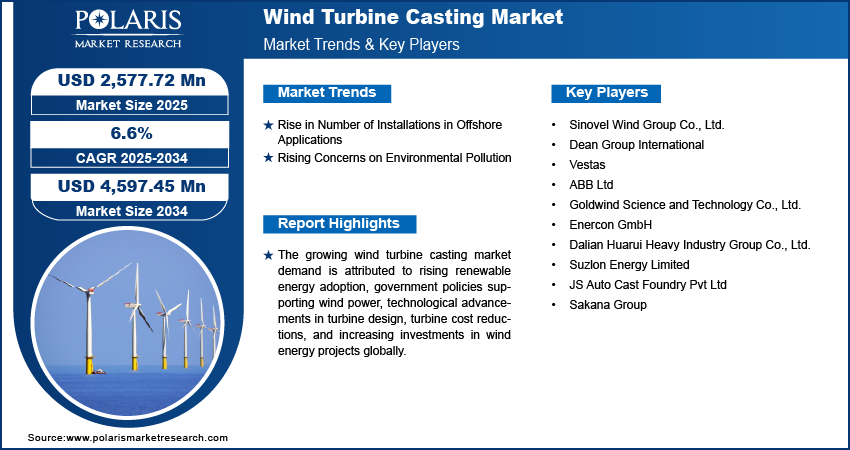

Wind Turbine Casting Market Projected to Reach USD 4,597.45 Million by 2034, Expanding at a CAGR of 6.6%

Market Overview

The wind turbine casting market is experiencing robust growth, driven by the global transition toward renewable energy. Cast components such as rotor hubs, gearbox housings, mainframes, and bearing housings are essential to the structural integrity and efficiency of wind turbines. These castings are typically produced from high-strength materials like ductile iron, steel, and aluminum alloys to ensure durability under varying weather and operational conditions. As demand for both onshore and offshore wind farms increases, the need for precision-engineered turbine castings is accelerating.

The global wind turbine casting market was valued at USD 2,418.35 million in 2024 and is expected to grow to USD 2,577.72 million in 2025. The market is projected to reach USD 4,597.45 million by 2034, registering a CAGR of 6.6% during the forecast period from 2025 to 2034.

Trends & Insights

-

Larger Turbines, Larger Castings: As wind turbine sizes increase to capture more energy, especially in offshore installations, the size and complexity of cast components are growing, demanding more advanced manufacturing techniques.

-

Adoption of Advanced Materials: The industry is shifting toward high-performance alloys and composite materials to reduce weight while maintaining strength, which improves efficiency and reduces maintenance needs.

-

Digitalization in Casting: Foundries are increasingly adopting digital simulation tools, 3D printing for mold design, and automation to enhance quality, reduce defects, and streamline production.

-

Sustainability and Circular Economy: Manufacturers are focusing on energy-efficient casting processes and recycling scrap materials to align with global sustainability goals and reduce carbon footprints.

-

Growth in Repowering Projects: Aging wind turbines, especially in developed regions, are being upgraded or replaced, creating a secondary market for replacement castings.

Market Size & Forecast

Market size value in 2025 USD – 2,577.72 million

Revenue forecast in 2034 USD – 4,597.45 million

CAGR – 6.6% from 2025 – 2034

Request for Free Sample: https://www.polarismarketresearch.com/industry-analysis/wind-turbine-casting-market/request-for-sample

Key Market Growth Drivers

-

Rising Renewable Energy Investments: Global efforts to reduce carbon emissions are pushing governments and private sectors to invest heavily in wind energy, fueling demand for high-quality cast turbine components.

-

Technological Advancements in Turbine Design: Innovations in turbine architecture and larger rotor diameters require more durable and precisely engineered castings.

-

Expansion of Offshore Wind Projects: Offshore wind energy is expanding rapidly due to higher and more consistent wind speeds, creating strong demand for robust castings that can withstand marine environments.

-

Government Incentives and Supportive Policies: Subsidies, tax credits, and renewable energy mandates are encouraging faster deployment of wind projects, directly impacting the casting market positively.

-

Growing Energy Demand: Increasing energy needs, particularly in developing economies, are being met through renewable sources like wind, boosting the market for supporting components like castings.

Market Challenges

-

High Production Costs: The large size and high precision requirements of wind turbine castings make them costly to manufacture, often requiring significant investment in foundry equipment and skilled labor.

-

Raw Material Price Volatility: Fluctuations in the prices of metals such as steel and aluminum can affect profit margins and pricing strategies.

-

Quality Control and Technological Complexity: As turbines become larger, maintaining casting quality and tolerances becomes more difficult, requiring advanced inspection and testing systems.

-

Supply Chain Disruptions: Geopolitical tensions, logistical challenges, and dependency on specific regions for raw materials or production facilities can impact timely delivery and overall market stability.

-

Environmental Regulations: Stricter environmental and emission norms related to foundry operations may increase compliance costs and affect smaller manufacturers.

In conclusion, the wind turbine casting market is poised for steady growth, supported by global clean energy initiatives and advancements in casting technologies. Addressing challenges such as cost pressures, quality assurance, and supply chain dependencies will be critical to sustaining momentum over the coming decade.