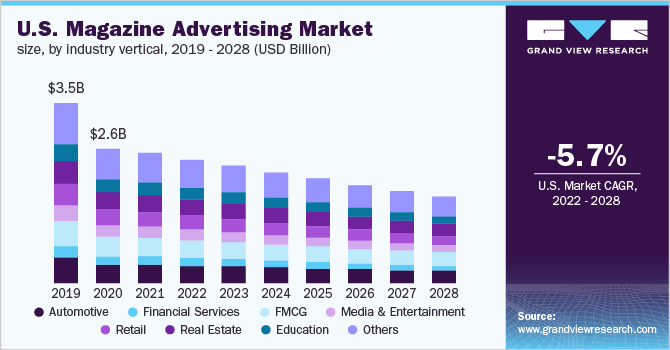

Vibration Monitoring Market Projected to Reach USD 5,192.99 Million By 2034, Growing at a CAGR of 6.4%

The global Vibration Monitoring market size was valued at USD 2,795.84 million in 2024 and is projected to grow from USD 2,970.58 million in 2025 to USD 5,192.99 million by 2034 , exhibiting a Compound Annual Growth Rate (CAGR) of 6.4% during the forecast period from 2025 to 2034 .

- Increasing Demand for Predictive Maintenance: Industries are increasingly adopting vibration monitoring systems as part of predictive maintenance strategies to detect early signs of equipment failure, reduce unplanned downtime, and optimize operational efficiency.

- Growth in Industrial Automation and Industry 4.0 Adoption: With the rise of smart manufacturing and Industrial Internet of Things (IoT) technology , there is a growing integration of real-time vibration monitoring solutions to enable condition-based maintenance and improve asset reliability.

- Expansion of Renewable Energy Infrastructure: The wind energy sector, in particular, is driving demand for vibration monitoring systems to ensure the smooth operation of turbines and prevent costly breakdowns in remote locations.

- Rising Emphasis on Safety and Asset Integrity in Oil & Gas and Power Generation Sectors: Critical machinery such as compressors, turbines, and pumps require continuous monitoring to avoid failures that could lead to safety hazards or environmental damage.

- Technological Advancements in Sensor Technology and Wireless Monitoring Systems: Innovations in wireless sensors, cloud-based analytics, and AI-driven diagnostics are enhancing the accuracy and scalability of vibration monitoring across industries.

Market Size & Forecast

- Market Size in 2024 – USD 2,795.84 million

- Market Size in 2025 – USD 2,970.58 million

- Projected Market Size by 2034 – USD 5,192.99 million

- CAGR (2025–2034) – 6.4%

Vibration monitoring involves the use of sensors and analytical tools to assess the mechanical health of rotating and reciprocating machinery in industrial settings. It plays a crucial role in detecting anomalies such as imbalance, misalignment, bearings wear, and rotor eccentricity—helping companies implement timely maintenance and avoid costly shutdowns.

The market is experiencing steady growth driven by the increasing adoption of condition-based maintenance practices, rising complexity of industrial machinery, and the need for cost-effective asset management solutions. Additionally, the expansion of IIoT platforms and digital twin technologies is enabling more sophisticated and integrated monitoring systems.

Technological innovation continues to shape the future of the vibration monitoring industry. Companies are launching compact, wireless, and self-powered sensor systems that can be easily retrofitted into existing infrastructure. Strategic partnerships between industrial automation providers and software analytics firms are accelerating the deployment of end-to-end predictive maintenance ecosystems. As global industries continue to modernize operations and emphasize uptime, the vibration monitoring market is poised for sustained growth over the next decade.