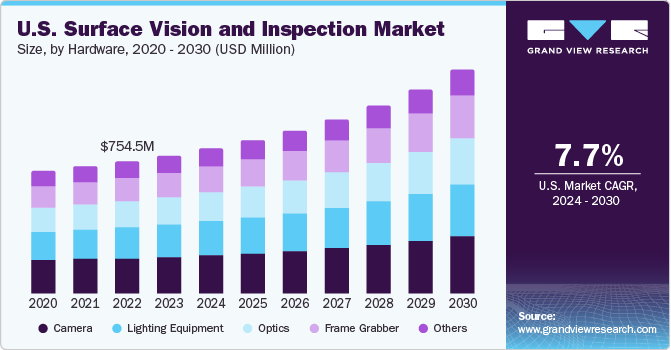

Surface Vision And Inspection Market Size, Share & Trends Analysis growing at a CAGR of 9.3% from 2024 to 2030

The global surface vision and inspection market size was estimated at USD 4.22 billion in 2023 and is projected to grow at a CAGR of 9.3% from 2024 to 2030. The increasing demand for 3D vision systems using laser triangulation across the healthcare sector and the automotive industry is expected to drive the market growth over the forecast period. Pharmaceutical companies require speedy and accurate inspection systems to detect and separate foreign materials from raw material components required to manufacture the final product.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/surface-vision-inspection-market/request/rs1

Laser technology is used in multiple ways for pharmaceuticals, mostly where traceability and security are vital considerations, such as the inspection of seal and blister in an insoluble product from the package.The growing preference for 3D technologies involving the use of a laser in the production line and complex applications such as paint and surface inspection of vehicles is anticipated to boost the surface vision and inspection market growth over the forecast period.

The machine learning approach to surface vision has helped in automating the design process of surface vision systems. This approach includes image acquisition, preprocessing, feature extraction, and classification. Furthermore, in-line image processing technology classifies, detects, filters, and maps specific defects accurately over the entire area of the surface. Improvements in these areas are anticipated to influence the growth of surface vision and inspection.

With the advancement of image processing technology, surface vision with charged coupled device cameras has enabled fast image acquisition and reduced false inspection rates. This has become widely used in industrial visual inspection, greatly improving production efficiency, and lowering the labor intensity of the workers. The focus on developing algorithms for machine learning integrated into vision systems with Convolution Neural Networks (CNN), Artificial Neural Networks (ANN), Support Vector Machine (SVM), and Extreme Learning Machine (ELM) is expected to drive the demand for vision systems on manufacturing floors over the forecast period.

Furthermore, the adoption of surface vision systems across different industries and sectors, such as electronics & semiconductors, food & beverage, and aerospace & defense, is anticipated to increase owing to the use of automation to lower operational costs, including the cost of labor. The implementation of surface vision systems in various production stages allows optimization of manufacturing expenditures, considerably benefiting in terms of overall operational spending. Thus, the advantages associated with vision systems and various technologies, such as machine learning and deep learning, are attracting manufacturers to adopt surface vision and inspection systems at a faster pace.

3D imaging technologies such as laser scanners can capture the depth and geometry of a surface, providing a more comprehensive picture of defects such as cracks, dents, and unevenness. Moreover, machine learning algorithms can be trained on vast datasets of images containing different components of defects. This allows them to automatically identify anomalies in real time, surpassing the limitations of human inspectors. In January 2024, Doss Visual Solution s.r.l., a machinery equipment provider, partnered with Pan Stone Europe Limited, a sales agency in Europe, to provide visual inspection systems to customers across Europe. Doss Visual Solution s.r.l. provides DOSS 3D Inspection System, which utilizes advanced technology to update 3D images of objects and evaluates them for any irregularities or defects. It is an optimal choice for industries that require accurate measurements and inspections, such as precision engineering and aerospace.

Market Concentration & Characteristics

Technological advancements are leading to the development of highly automated surface vision systems through the use of machine learning, such as extreme learning machines and artificial neural networks. Further, the increasing use of big data and internet of things is emerging as a key trend for implementing Industry 4.0 aimed at interconnecting people, machines, production resources, and products online.

The global cyber security market is also witnessing a high level of merger and acquisition initiatives by various leading and emerging players. For instance, in November 2023, Industrial Vision Systems Ltd. was acquired by Oxford Metrics, a UK-based smart sensing software company. The company was acquired at an amount of EUR 8.10 million (USD 8.83 million). The acquisition helped Oxford Metrics expand its footprints in the surface vision and inspection market.