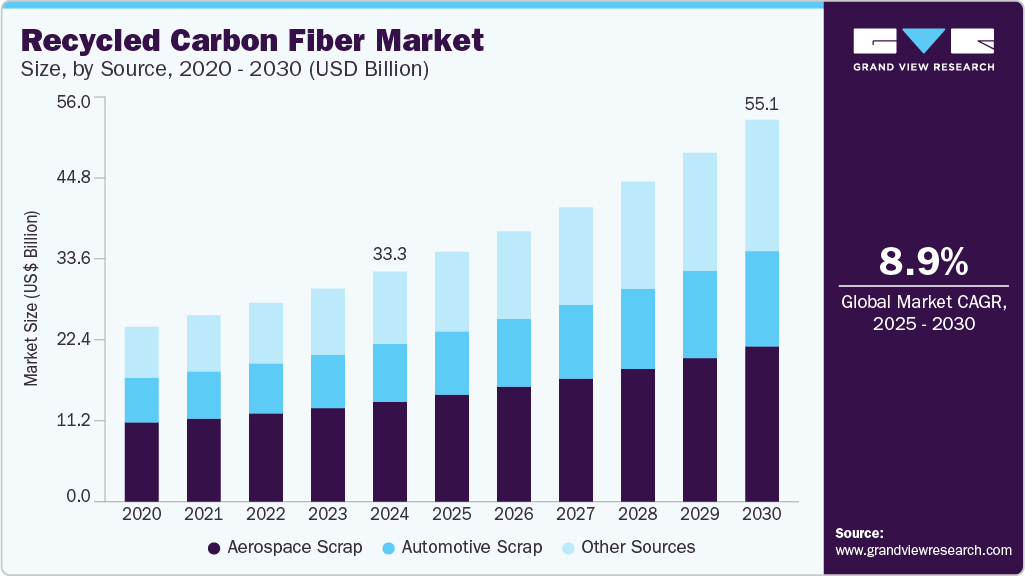

Recycled Carbon Fiber Market Size, Share & Trends Analysis growing at a CAGR of 8.9% from 2025 to 2030

The global recycled carbon fiber market size was estimated at USD 33.31 billion in 2024 and is projected to grow at a CAGR of 8.9% from 2025 to 2030. A primary driving force is the increasing global emphasis on sustainability and the circular economy, compelling industries to reduce waste and carbon footprints.

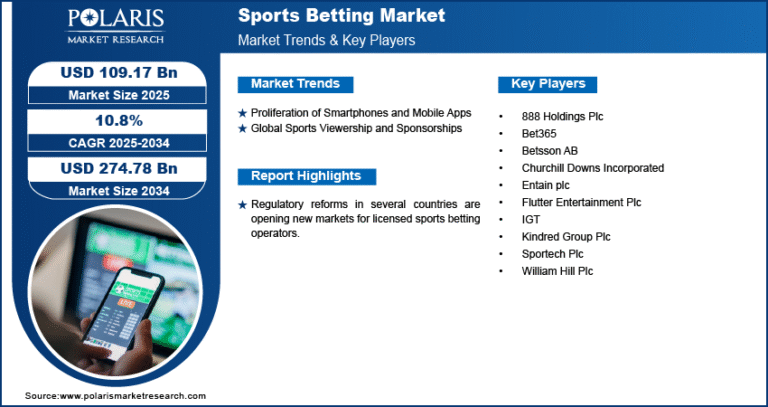

Key Highlights:

- The recycled carbon fiber market in Asia Pacific accounted for the largest revenue share of 28.6% in 2024

- The U.S. dominated the recycled carbon fiber industry in 2024.

- By source, the aerospace scrap segment dominated the market, accounting for 43.3% of the revenue share in 2024.

- By type, the chopped fiber segment dominated the market in 2024.

- By end use, the automotive & transportation segment dominated the recycled carbon fiber industry in 2024.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/recycled-carbon-fiber-market-report/request/rs1

Recycled carbon fiber offers a compelling alternative to virgin carbon fiber, providing similar performance characteristics at a significantly lower cost. Key end use industries, including automotive, aerospace, wind energy, and sporting goods, are increasingly incorporating recycled carbon fiber due to its lightweight properties. For instance, in April 2024, UBE Corporation, a chemical company, introduced new composite products incorporating recycled carbon fiber. These composites, developed by integrating recycled carbon fiber into various nylons and enhancing their functionalities, are targeted for applications in industries such as automotive and sports. This innovation aims to decrease energy consumption by reducing the weight and improving the performance of various components while also lowering greenhouse gas emissions associated with carbon fiber production.

Technological advancements are continuously refining recycling processes and improving the quality and efficiency of reclaimed fibers. Pyrolysis, which involves heating carbon composites in an oxygen-free environment to remove resin, is a prominent method, with advancements like microwave recycling significantly reducing energy consumption. In March 2025, the Fraunhofer Institute for High-Speed Dynamics developed a pyrolysis process for recycling carbon fibers from thermosetting composites. This method efficiently reclaims fibers from used composites, particularly continuous carbon fiber rovings found in high-pressure hydrogen tanks, without compromising their mechanical properties. Solvolysis, particularly supercritical water and glycolysis techniques, is also gaining traction for its ability to recover near-virgin-quality fibers. These advancements aim to minimize fiber degradation during recycling, allowing for the retention of near-virgin-like mechanical properties, thus expanding their applicability in high-performance components. In addition, advancements in manufacturing processes, such as additive manufacturing and precision molding techniques, are enabling the integration of recycled carbon fiber into a wider array of products, further solidifying its position as a sustainable and economically attractive material solution.