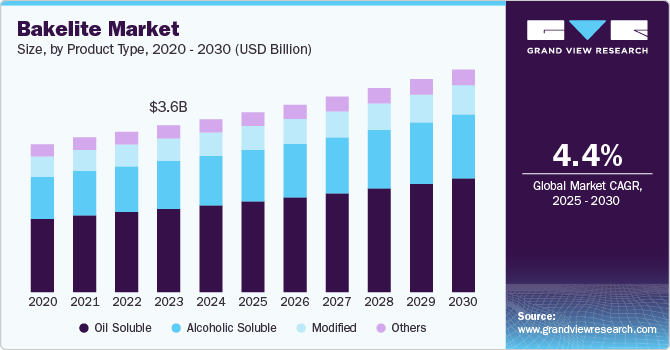

Bakelite Market Size, Share & Trends Analysis grow at a CAGR of 4.35% from 2025 to 2030

The global Bakelite market size was estimated at USD 3.68 billion in 2024 and expected to grow at a CAGR of 4.35% from 2025 to 2030. The growing demand for fire-resistant product types in the construction and automotive industries is driving the use of Bakelite, as it offers excellent thermal stability and flame-retardant properties.

The Bakelite industry is witnessing a resurgence in demand due to the growing preference for high-performance, heat-resistant, and electrically insulating materials across multiple industries. In sectors like electronics, automotive, and aerospace, Bakelite’s superior mechanical strength and thermal stability make it an attractive alternative to conventional plastics and metals. Additionally, as industries push for lightweight and durable components, Bakelite’s ability to replace heavier materials in electrical housings, brake pads, and circuit boards is driving its relevance. Moreover, with the increasing adoption of phenolic resins in sustainable product designs, manufacturers are investing in advanced Bakelite formulations to enhance performance while aligning with environmental regulations.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/bakelite-market/request/rs1

Drivers, Opportunities & Restraints

The rapid expansion of the electrical and electronics industry is a key driver for the Bakelite market, as its exceptional insulating properties and high resistance to heat make it indispensable in switchboards, circuit breakers, and electrical panels. With the rise in global electrification projects, smart grid development, and the proliferation of consumer electronics, the need for thermosetting plastics like Bakelite is on an upward trajectory. Furthermore, industries are shifting toward more durable and low-maintenance materials, increasing the adoption of Bakelite in high-voltage insulation systems and precision engineering applications. Its cost-effectiveness and longevity compared to other polymers also add to its competitive advantage in industrial applications.

The push for sustainable material innovation presents a significant opportunity for the market, especially with advancements in bio-based phenolic resins. As regulatory frameworks tighten around hazardous chemicals and carbon-intensive manufacturing, there is a growing incentive for companies to develop eco-friendly alternatives to traditional Bakelite formulations. By integrating renewable feedstocks and improving recyclability, manufacturers can cater to sustainability-focused industries such as green electronics and renewable energy infrastructure. Additionally, expanding industrial applications in emerging markets, particularly in Asia-Pacific and Latin America, provide new revenue streams for market players looking to capitalize on increasing manufacturing activity and infrastructure development.

Despite its industrial advantages, the Bakelite industry faces constraints due to environmental concerns and regulatory limitations regarding formaldehyde-based resins. The production process involves hazardous chemicals that raise safety and environmental compliance challenges, especially in regions with strict emission standards. Additionally, the material’s brittle nature limits its use in applications requiring high impact resistance, reducing its competitiveness against advanced polymers and composites. Furthermore, as industries increasingly adopt alternative thermosetting resins with enhanced flexibility and sustainability profiles, Bakelite’s growth potential may be hindered unless innovations in formulation and processing technology address these limitations.