Aseptic Connectors & Welders Market Size, Share & Trends Analysis growing at a CAGR of 14.96% from 2025 to 2033

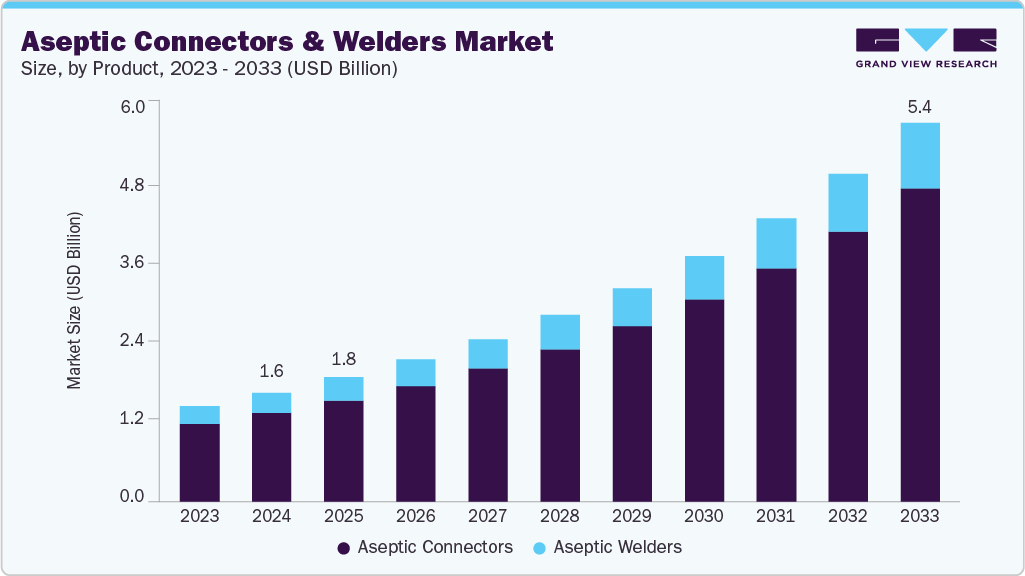

The global aseptic connectors & welders market size was estimated at USD 1.55 billion in 2024 and is projected to reach USD 5.39 billion by 2033, growing at a CAGR of 14.96% from 2025 to 2033. This growth is driven by increasing demand for sterile fluid transfer solutions in the biopharmaceutical, food & beverage, and healthcare industries, where maintaining product purity and process integrity is critical.

Key Market Trends & Insights

- In terms of region, North America held the largest revenue share of 48.11% of the global market in 2024.

- The aseptic connectors & welders industry in the U.S. is expected to grow significantly over the forecast period.

- By product, the aseptic connectors segment held the highest market share in 2024.

- Based on application, the upstream bioprocessing segment held the highest market share of 45.19% in 2024.

- By end use, the OEMs segment held the highest market share of 39.02% in 2024.

Market Size & Forecast

- 2024 Market Size: USD 1.55 Billion

- 2033 Projected Market Size: USD 5.39 Billion

- CAGR (2025-2033): 14.96%

- North America: Largest market in 2024

- Asia Pacific: Fastest growing market

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/aseptic-connectors-welders-market-report/request/rs1

Furthermore, advancements in single-use technologies, stricter regulatory requirements, and rising investments in biologics manufacturing accelerate market expansion.

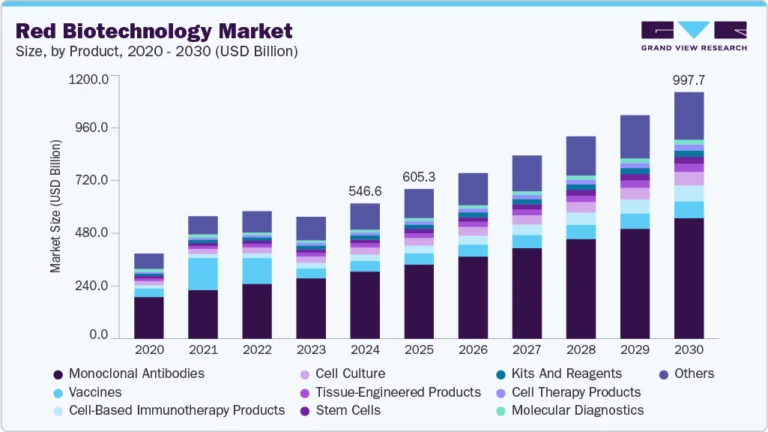

Growth of the biopharmaceutical industry

The growth of the biopharmaceutical industry is a major driver of the market. As the demand for complex biologics such as monoclonal antibodies, cell and gene therapies, and mRNA vaccines increases, manufacturers are under pressure to ensure contamination-free, sterile production environments. These high-value biologics are extremely sensitive to microbial contamination, making sterile fluid transfer a critical requirement. Aseptic connectors and welders enable secure, closed-system processing that ensures product integrity while meeting strict regulatory standards. The shift from stainless steel equipment to single-use systems (SUS) has also accelerated the need for reliable aseptic connection technologies that can support flexible and scalable production setups.

Moreover, the rapid advancement of cell and gene therapies, such as CAR-T cell treatments and personalized gene editing, further drives the demand for aseptic connection solutions. These therapies are typically produced in small, patient-specific batches, requiring highly sterile, adaptable workflows with frequent connections and disconnections. Aseptic connectors that offer ease of use, sterility assurance, and scalability are essential to support these complex processes. For instance, in April 2021, CPC emphasized adopting Single-Use Technology (SU and gene therapy (CGT) manufacturing to address scalability challenges.