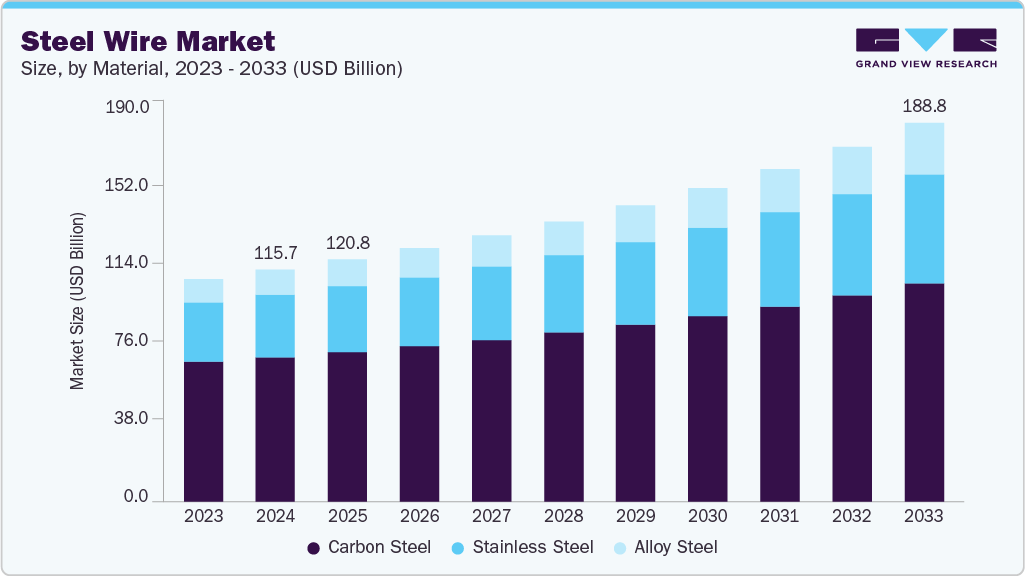

Steel Wire Market Size, Share & Trends Analysis growing at a CAGR of 5.7% from 2025 to 2033

The global steel wire market size was estimated at USD 115.68 billion in 2024 and is projected to reach USD 188.76 billion by 2033, growing at a CAGR of 5.7% from 2025 to 2033. The market is growing mainly because of the number of construction and infrastructure projects worldwide.

Key Market Trends & Insights

- Asia Pacific dominated the steel wire market with the largest revenue share of 54.4% in 2024.

- The steel wire industry in the U.S. is expected to grow at a substantial CAGR of 4.6% from 2025 to 2033.

- By material, the carbon steel segment accounted for the largest revenue share of over 62.5% in 2024.

- By application, the agriculture segment is anticipated to register the fastest CAGR of 8.7% from 2025 to 2033.

Market Size & Forecast

- 2024 Market Size: USD 115.68 Billion

- 2033 Projected Market Size: USD 188.76 Billion

- CAGR (2025-2033): 5.7%

- Asia Pacific: Largest market in 2024

- Latin America: Fastest growing market

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/steel-wire-market-report/request/rs1

Steel wires are widely used in bridges, roads, buildings, and other large structures. They help strengthen concrete and are also used for fencing and safety barriers. Many countries, especially developing ones like India, China, and Southeast Asian countries, are investing heavily in improving their infrastructure. Governments are spending more on smart cities, highways, metros, and power lines, which increases the demand for steel wires. As construction activities continue to grow, the need for steel wire will also keep rising.

Governments across Asia, Africa, and Latin America are heavily investing in transportation networks, bridges, railways, and urban infrastructure. For instance, India’s “PM Gati Shakti” master plan involves a multi-billion-dollar logistics and infrastructure investment requiring massive structural steel. Similarly, China’s Belt and Road Initiative (BRI), which spans over 60 countries, continues to catalyze steel demand through large-scale construction and transportation projects.

The automotive industry remains a robust consumer of steel, particularly in producing car bodies, engines, chassis, and safety components. With the global shift toward electric vehicles (EVs), manufacturers increasingly use high-strength, lightweight steel to reduce vehicle weight while maintaining crash safety and structural integrity. For instance, General Motors and Toyota have adopted advanced high-strength steel (AHSS) in their EV platforms to balance durability and fuel economy. According to the International Energy Agency (IEA), global electric car sales reached approximately 17 million units in 2024, up from 14 million in 2023, accounting for nearly one in every five cars sold. This rapid EV adoption has significantly bolstered demand for specialized automotive steel grades, particularly cold-rolled and galvanized steel used in battery enclosures, motor housings, and lightweight body structures. Key manufacturing hubs like China, Germany, and the U.S. are leading this trend, supporting steady steel consumption from the transportation sector.

The shift toward renewable energy has created a surge in demand for specialized steel for producing wind turbines, solar mounting systems, and hydroelectric infrastructure. For instance, offshore and onshore wind farms require large quantities of steel for towers, foundations, and nacelle components. An example is the Hornsea Project in the UK, the world’s largest offshore wind farm, which uses over 200,000 tons of steel. Additionally, transmission towers and electric grids, necessary to support renewable integration, continue to be built using galvanized and structural steel.

Urbanization and population growth drive a strong demand for residential and commercial real estate, fueling the need for structural steel products such as rebar, beams, columns, and sheets. The U.S. residential housing market has seen consistent growth post-pandemic, and countries like Saudi Arabia are developing futuristic smart cities like NEOM, which are projected to use over 1.5 million tons of steel in their initial construction phases alone. Real estate expansion in Southeast Asia, particularly Vietnam and Indonesia, also accelerates steel consumption for high-rise and mid-level developments.

Drivers, Opportunities & Restraints

Strong demand from key industries such as construction, automotive, and manufacturing drives the growth of the steel wire industry. As infrastructure projects expand globally, especially in developing regions like Asia-Pacific and the Middle East, the use of steel wire in bridges, buildings, and roads is growing rapidly. In the automotive industry, steel wire is essential for springs, tire reinforcements, and control cables. Additionally, industrial sectors such as mining, oil & gas, and marine operations rely on high-strength steel wire ropes for lifting and hauling, further supporting market growth. Technological advancements in wire drawing and coating have also made steel wire more durable and corrosion-resistant, boosting its appeal across end-use industries.

Several promising opportunities exist in the steel wire market. With the global shift toward EVs and renewable energy, there is a rising demand for specialty wires that are lightweight, strong, and heat-resistant. Furthermore, the growth of smart cities and 5G infrastructure offers new avenues for using fine steel wires in telecommunication cables and energy grids. Emerging markets in Africa and Southeast Asia present untapped potential due to rapid urbanization and government investment in infrastructure. Developing eco-friendly and recyclable steel wire products is another opportunity, as sustainability becomes a priority for many industries and governments.

Despite its growth, the steel wire industry faces several challenges. One major constraint is the volatility in raw material prices, especially steel and related alloys. Fluctuating input costs can directly impact production and profitability for manufacturers. Additionally, the market is highly energy-intensive and subject to strict environmental regulations in several countries, which may increase compliance costs and slow expansion.