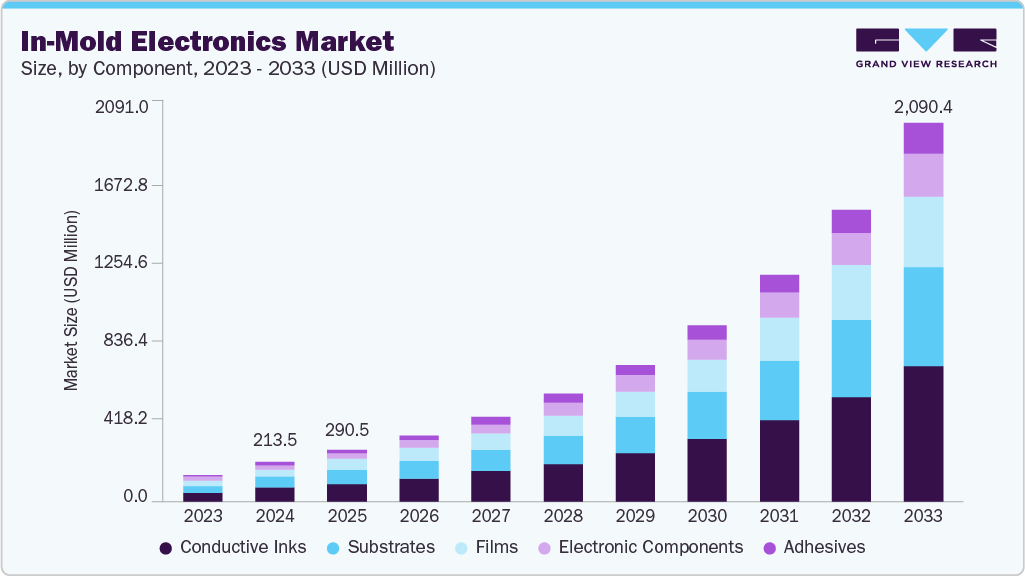

In-Mold Electronics Market Size, Share & Trends Analysis growing at a CAGR of 27.9% from 2025 to 2033

The global in-mold electronics market size was estimated at USD 213.50 million in 2024, and is projected to reach USD 2,090.42 million by 2033, growing at a CAGR of 27.9% from 2025 to 2033, driven by the increasing demand for lightweight, compact, and cost-effective electronic components integrated directly into molded surfaces.

Key Market Trends & Insights

- The Asia Pacific in-mold electronics market accounted for a 48.6% share of the overall market in 2024.

- The In-Mold electronics market in China held a dominant position in 2024.

- By component, the conductive Inks segment accounted for the largest share of 35.2% in 2024.

- By technology, the screen printing segment held the largest market share in 2024.

- By end use, the automotive segment dominated the market in 2024.

Market Size & Forecast

- 2024 Market Size: USD 213.50 Million

- 2033 Projected Market Size: USD 2,090.42 Million

- CAGR (2025-2033): 27.9%

- Asia Pacific: Largest market in 2024

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/in-mold-electronics-market-report/request/rs1

The rising adoption of smart surfaces in automotive interiors, consumer electronics, and industrial applications, combined with advances in printed electronics, capacitive touch sensors, and decorative-functional integration, is significantly accelerating market growth across developed and emerging regions. The growing shift toward electric vehicles and intelligent automotive interiors is significantly boosting the market for In-Mold electronics. Automakers are under continuous pressure to reduce vehicle weight and enhance energy efficiency while maintaining high-performance standards. IME allows the integration of printed circuitry, lighting, and sensors into 3D-molded plastic parts, replacing bulky wiring harnesses and mechanical buttons. This results in a sleeker, lighter, and more energy-efficient design. As OEMs push for innovation in human-machine interfaces (HMIs), steering consoles, and infotainment systems, the need for compact, multifunctional components is propelling the market growth of IME within the global automotive industry.

The rising consumer demand for aesthetically pleasing and durable interfaces in products like smart home appliances, smartphones, and wearable electronics is propelling the market growth of IME technology. In-Mold Electronics enables the embedding of capacitive touch sensors and LEDs into curved or contoured surfaces, allowing for next-generation product designs. Its resistance to abrasion, moisture, and chemical exposure makes it ideal for household and portable electronics that require high reliability in daily use. As device miniaturization and multifunctionality become essential, manufacturers are increasingly shifting toward IME-enabled solutions to meet modern consumer expectations, thereby boosting the market.

Government-backed research and development in printed electronics and hybrid systems is further boosting the market for In-Mold Electronics. Multiple national programs and innovation consortia have been launched to support the advancement of flexible, formable, and printed electronics, which are foundational to IME technology. These initiatives are not only fostering innovation in conductive inks and flexible substrates but are also accelerating commercialization pathways for IME applications across sectors. As collaborative ecosystems between public institutions and industrial players strengthen, the resulting technological breakthroughs are enhancing manufacturing capabilities and propelling the market growth for IME on a global scale.

The global emphasis on sustainable electronics and eco-friendly manufacturing is strongly encouraging the adoption of IME over traditional circuit-based systems. IME structures use fewer materials, reduce the need for hazardous substances, and simplify recycling at end-of-life. These advantages align well with environmental regulations and circular economy models adopted by many governments and industries. As companies move toward greener product development and regulatory compliance, IME is emerging as a preferred technology due to its sustainable attributes. This focus on environmental responsibility is propelling the market growth of IME, particularly in consumer electronics, appliances, and automotive interiors.

Component Insights

The Conductive Inks segment accounted for the largest share of 35.2% in 2024. The adoption of conductive inks is playing a pivotal role in propelling the market growth of In-Mold Electronics. These inks serve as the foundation for creating flexible and stretchable circuitry, enabling electronics to be embedded within 3D-formed plastic parts. As industries push for thinner, lighter, and more integrated designs, the demand for silver-based and carbon-based conductive inks is accelerating. Enhanced conductivity, printability, and thermal stability make these inks indispensable in forming complex circuit patterns in curved IME surfaces. Moreover, ongoing innovation in nano-particle inks and printable dielectric materials is further boosting the market by enabling high-performance electronic integration at scale.

The Electronic Components segment is projected to grow at a significant CAGR over the forecast period. The increasing functionality of In-Mold Electronics is supported by advancements in electronic components such as sensors, LEDs, and capacitors. These components are now being developed in ultra-thin formats, enabling seamless integration within molded structures. The growing need for capacitive touch sensing, embedded lighting, and wireless interfaces in automotive and consumer electronics is driving demand for these components. Their compact size and compatibility with flexible substrates are essential for next-generation IME applications. As industries continue to prioritize space-saving solutions with multifunctionality, the innovation in embedded components is directly boosting the market for IME-based systems.